I keep waiting for something to go horribly wrong.

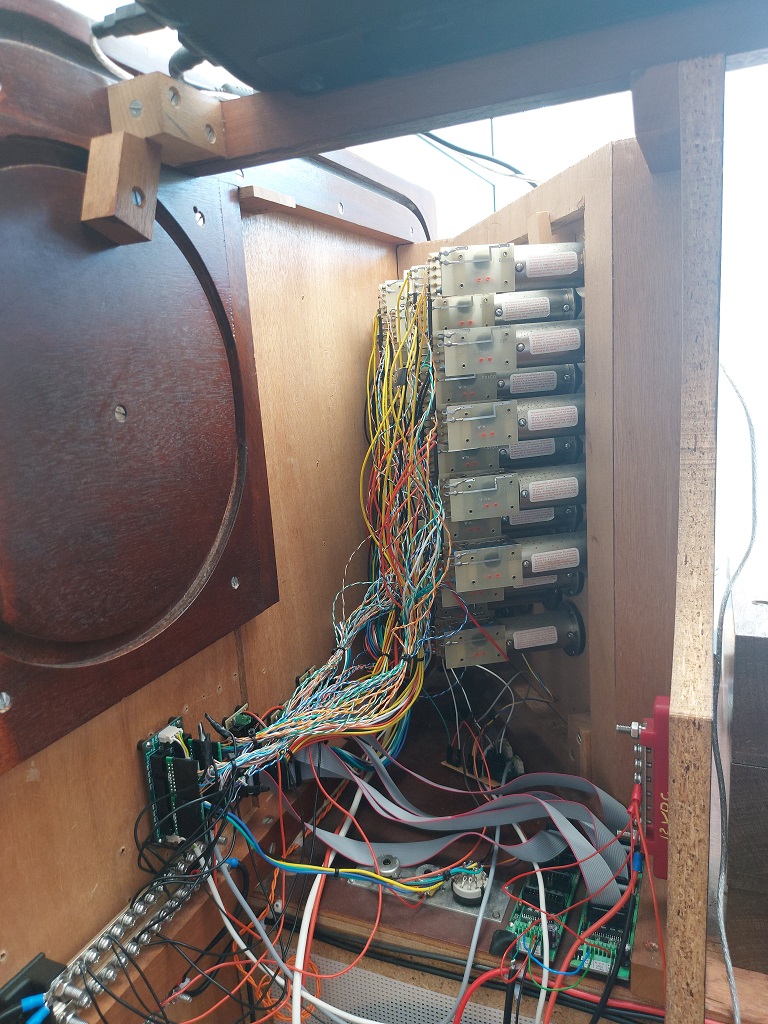

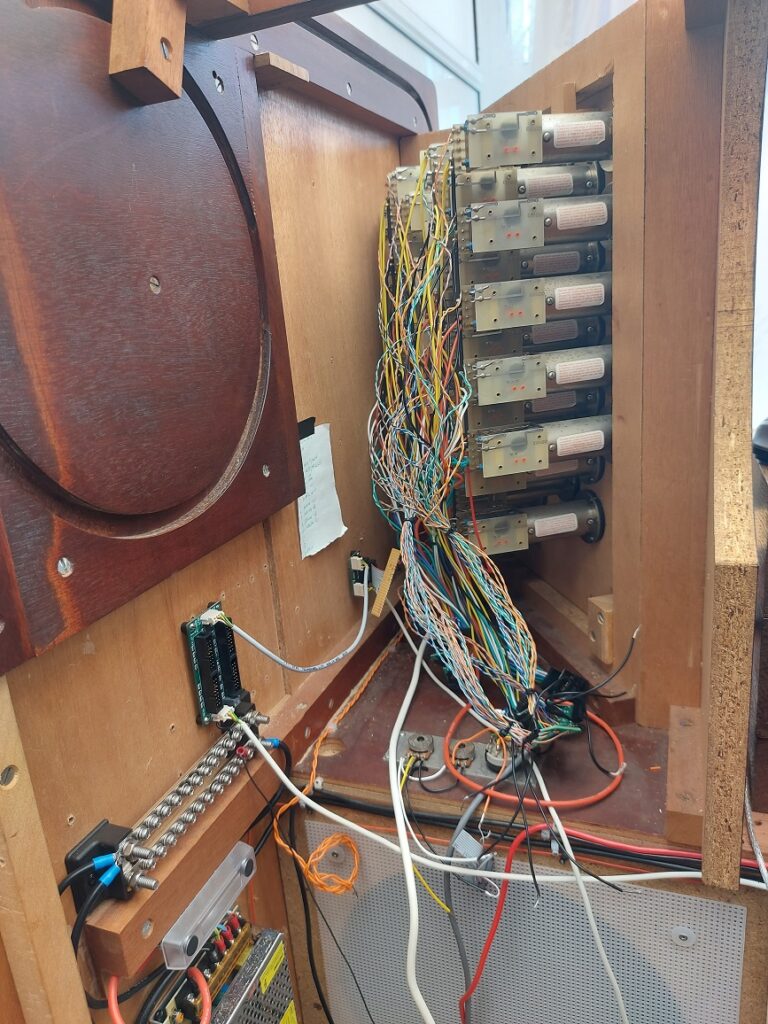

Following on from yesterday’s success, I was able to confirm today that the reed switches are all behaving properly. This means that both stop jambs are now functional. I still have to program the BBS-1K modules that they plug into, but that’s a trivial detail (he said, sealing his fate). Today’s activity centred around unscrewing the manuals. I didn’t think I’d have to do that again, but there you go.

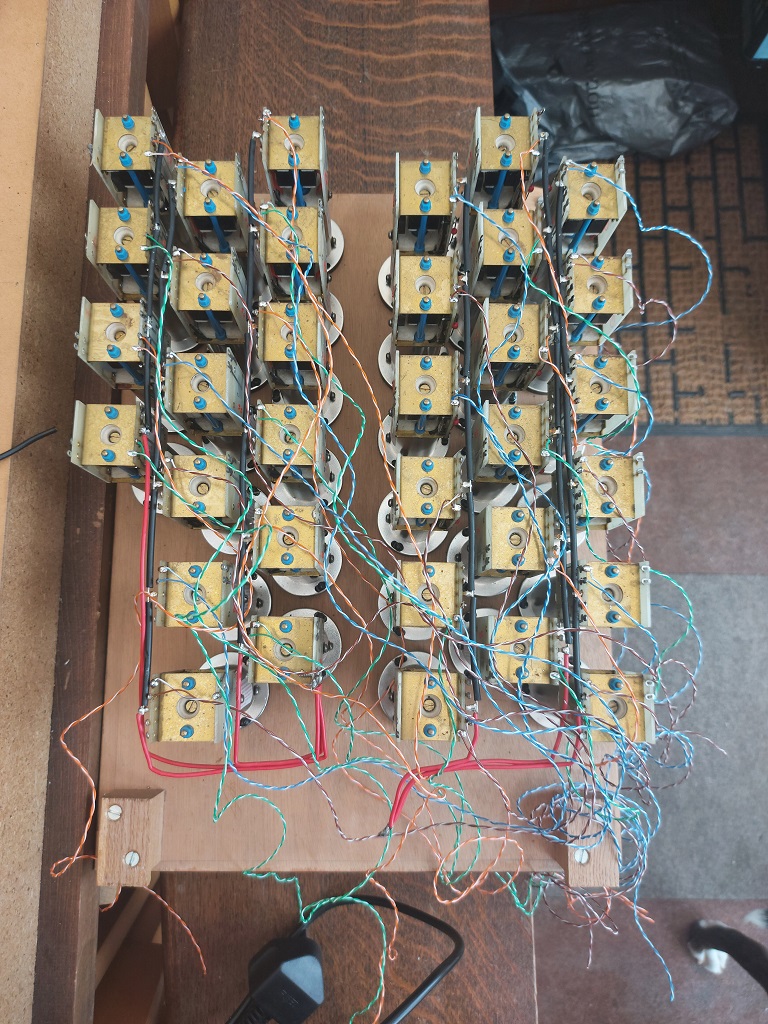

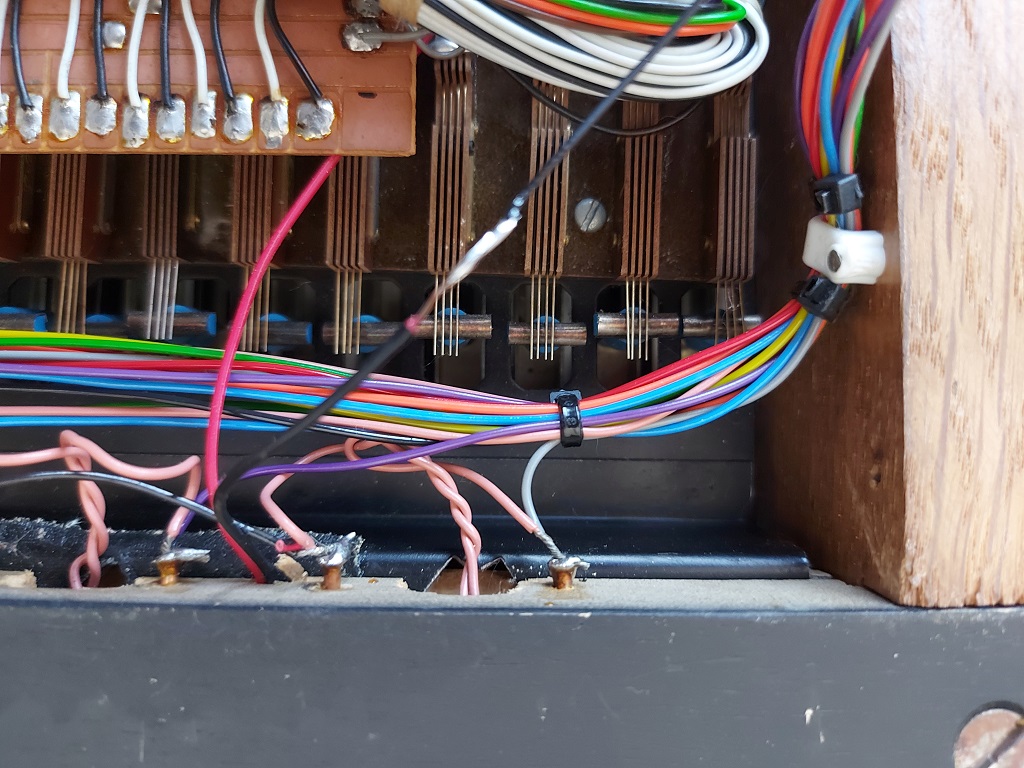

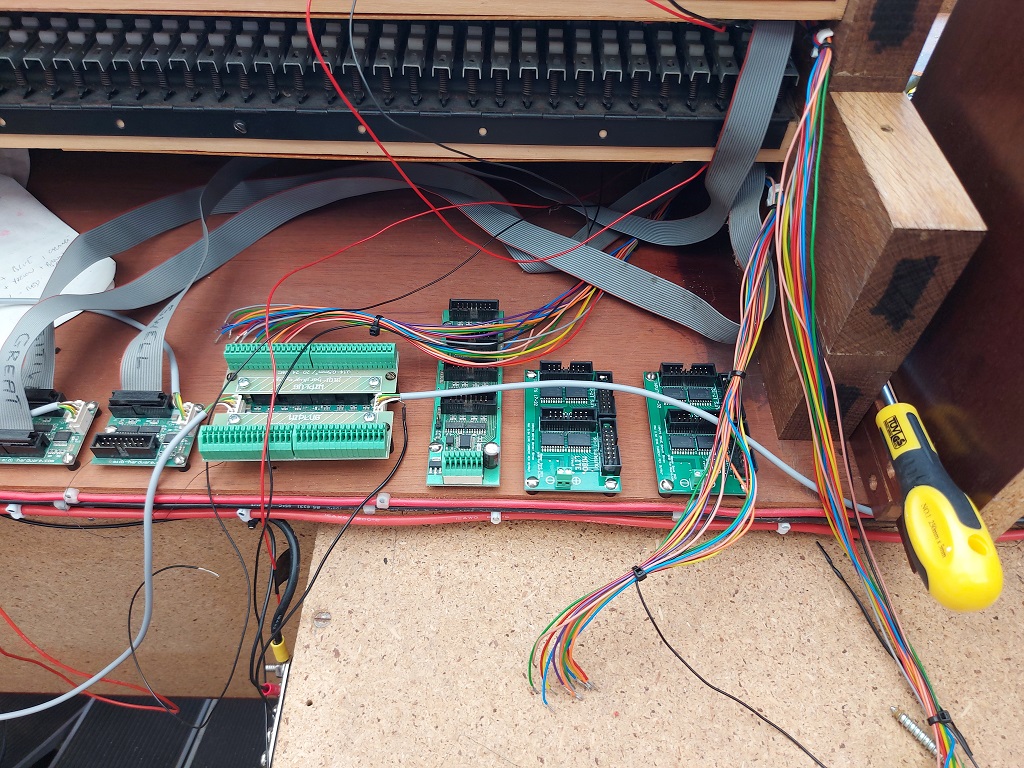

When I first wired up the manuals, I connected the 0V wire of the LED to the common ground of the thumb pistons. Now I come to actually wire them up, I realise that this is incorrect. The LEDs will be driven by another MIDECO module, via a MIBO-LITE board. This requires the 12V connection to be “always on”, and the 0V connection is made or broken by the MIBO-LITE. This necessitated a quick soldering job on the underside of each keyboard, to break the connection to the common ground and attach a long lead for connection to the module. What larks!

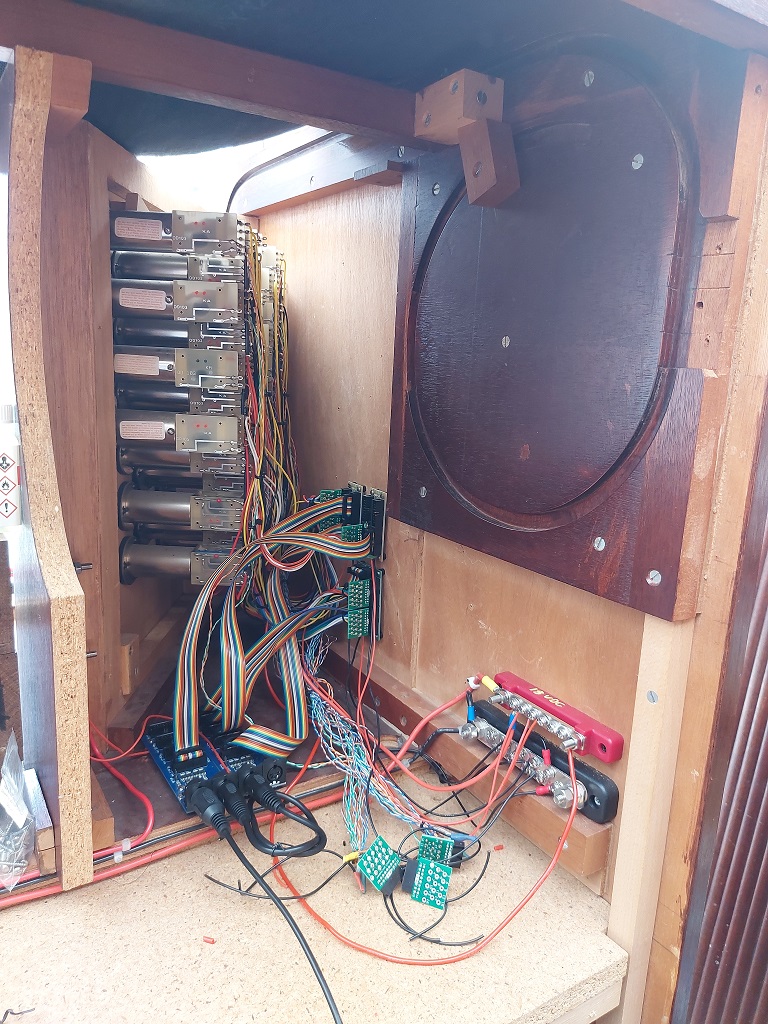

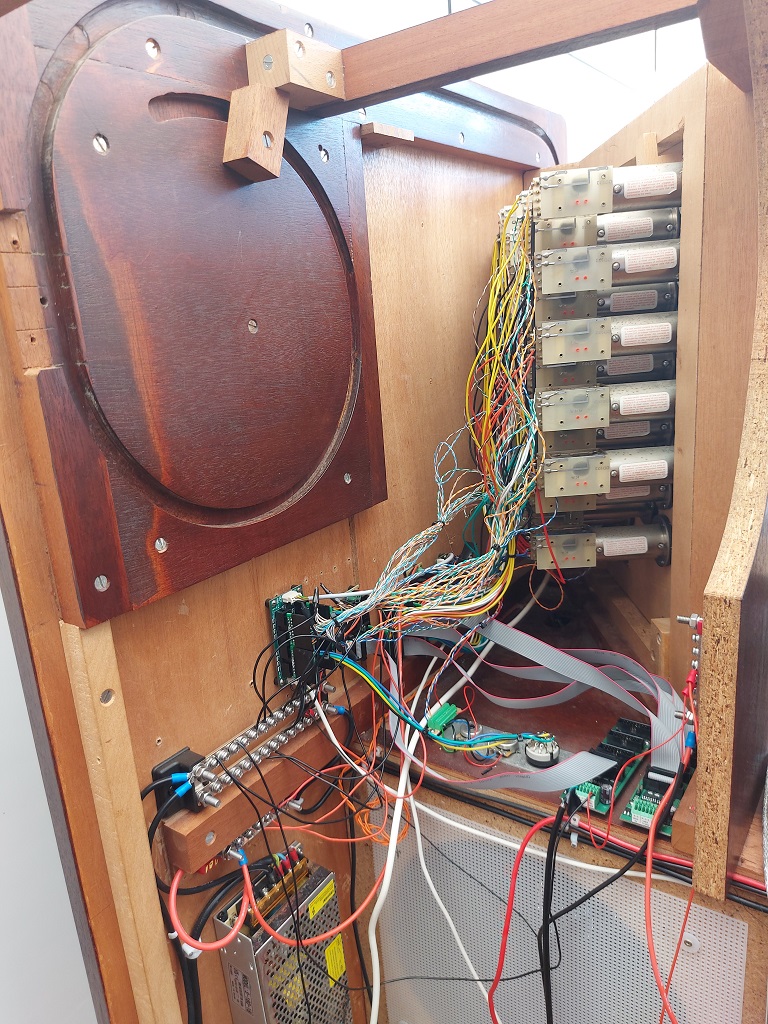

While the keyboards were disconnected, I took the opportunity to screw down the boards which will turn LEDs on and off. Apart from the three on the manuals, there will be another 32 behind the rocker tabs. “Rocker tabs, you say?” (I hear you cry.) More about them at a later date.

David has promised to return the toe pistons Real Soon Now™ and then I should be in a position to make the organ playable again. I miss it.