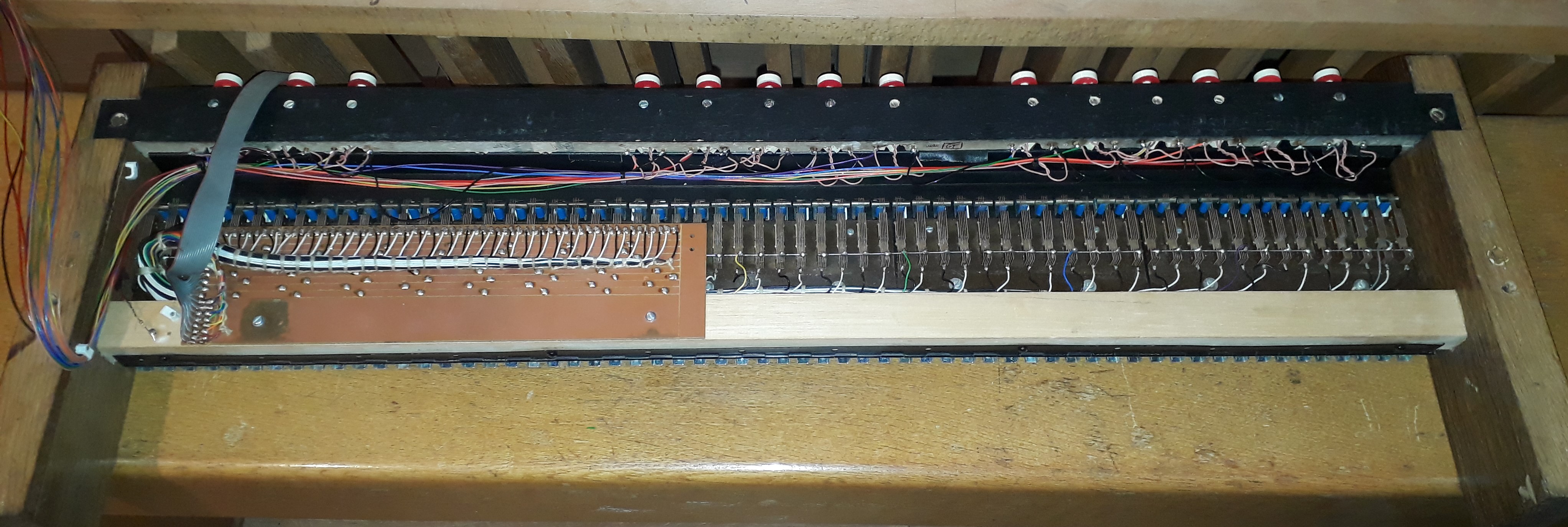

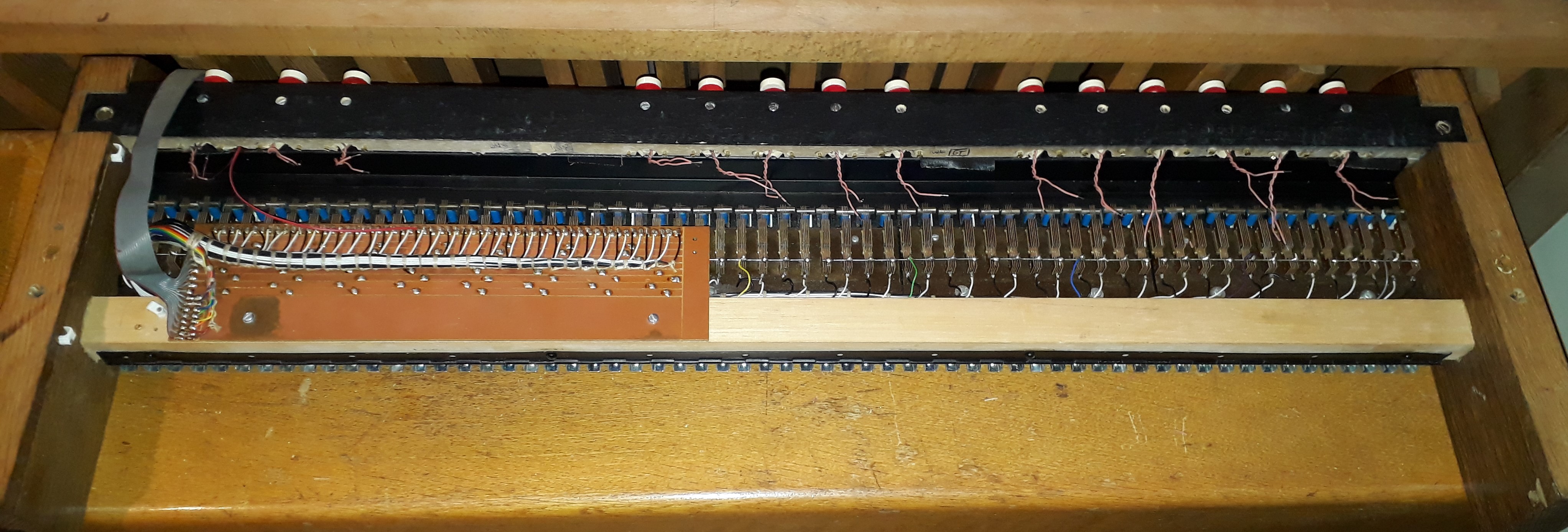

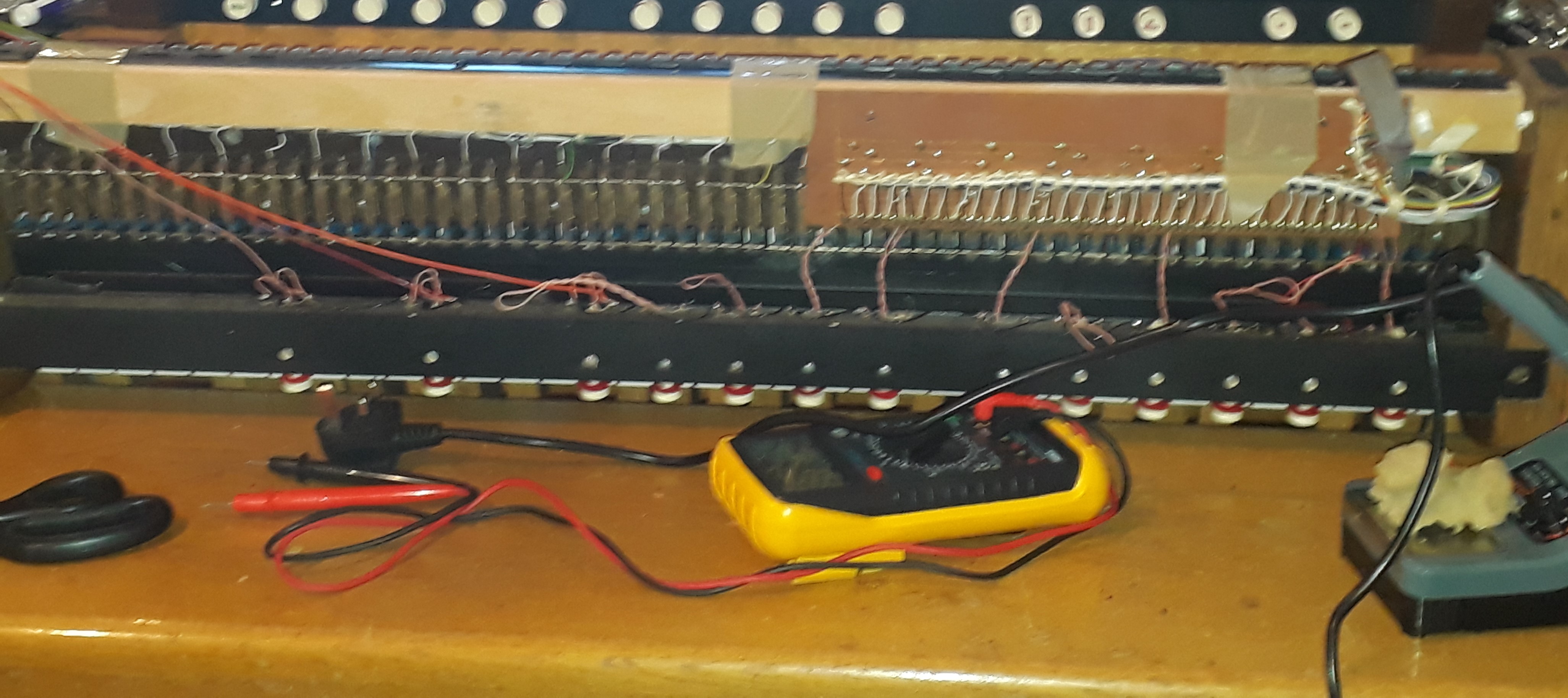

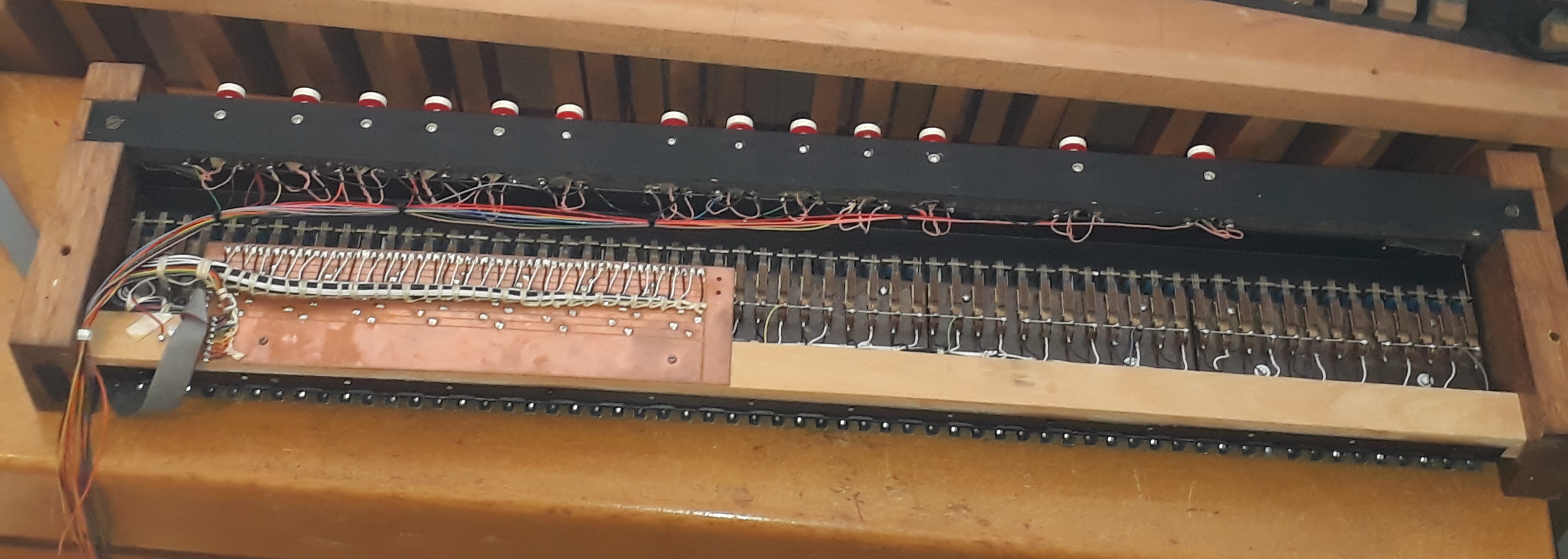

So, chatting to the friendly organ engineer about the problems I was having with getting the solder to adhere to the nasty nickel-plated steel screws, I got a wise “yes, they’ll do that” sort of response. The replacement brass screws were duly purchased, 96 steel screws were unscrewed, and 96 brass alternatives were installed. Some of the holes are a little loose, which is irritating, but should easily be secure enough to remain where they are supposed to remain. A spot of epoxy might be in order.

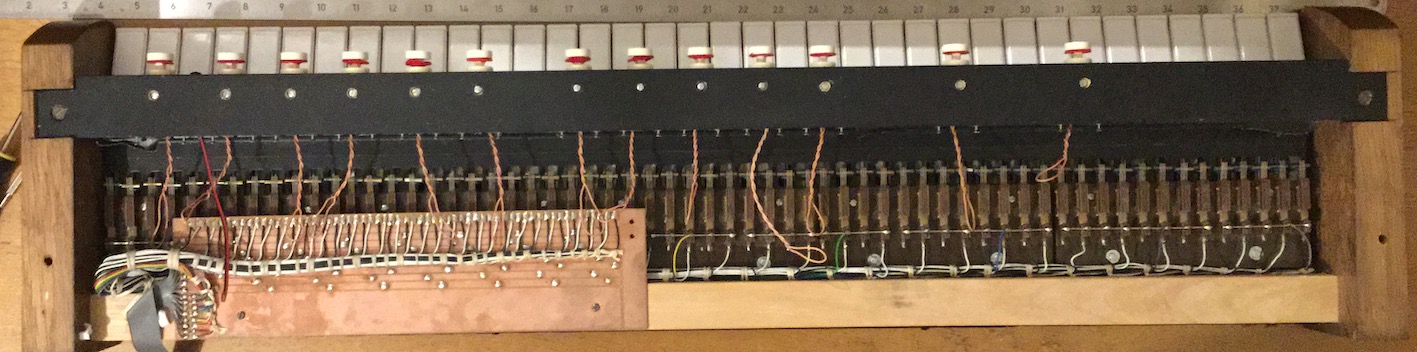

Now I’m beginning the labourious process of soldering two or three wires to each post. This is challenging to say the least. I’m waiting for the arrival of some helping hands, which I hope will make it less awkward.

All my jobs are running somwehat slowly at present, due to the news I received last week that poor Mia has inoperable cancer. She’s soldiering on, aided by copious quantities of painkillers, and is dividing her time between sleeping, eating and watching squirrels. She seems quite happy at the moment, but her days are numbered, quite severely. A few weeks at best.