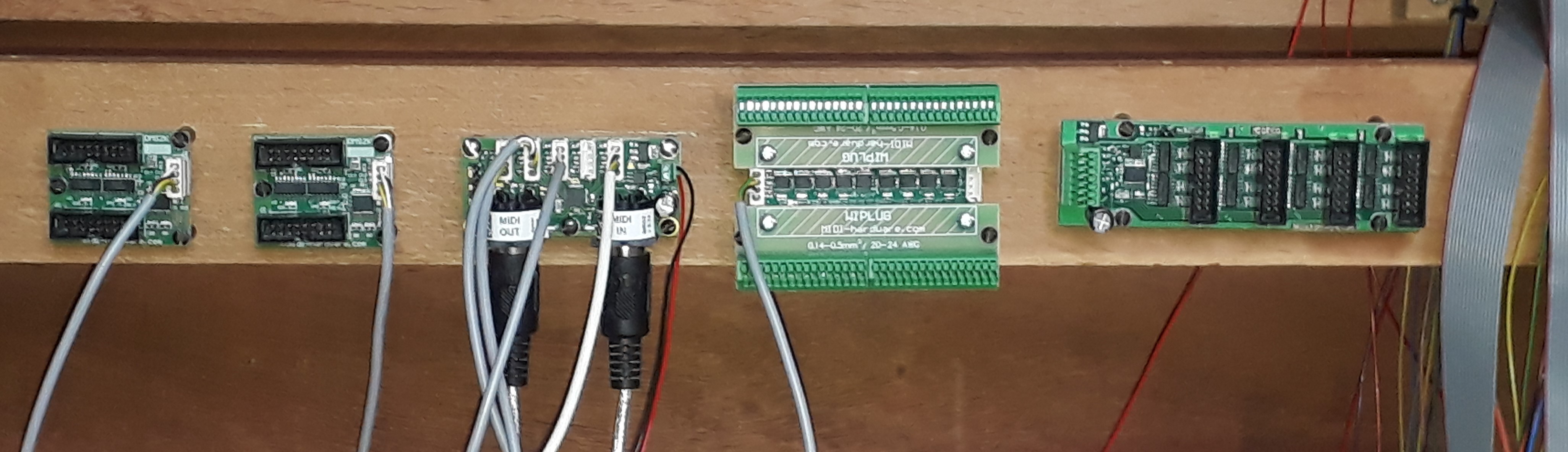

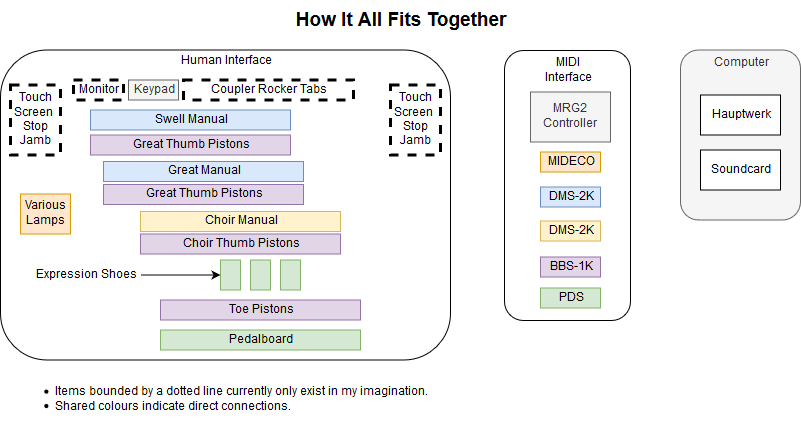

Not much free time this weekend, but there’s not a lot I can do with the organ at the moment either. I am waiting for some nylon stand-offs to arrive (around Wednesday, I estimate) so that I can affix the various MIDI components to the console. Once that is done, I will begin the laborious process of connecting up the pistons. The MIDI channels I will be using are:

1: Great

2: Swell

3: Choir

4: Pedal

5: Pistons (thumb and toe)

6: Tabs

7: Control

…although this scheme is subject to alteration approximately as and when I feel like it. I also have to read the documentation to see if the toe pistions go through the pedal controller. I know the expression pedals do. I would prefer all the pistons to go through a single controller and on a single channel, but I’m not wedded to the idea.

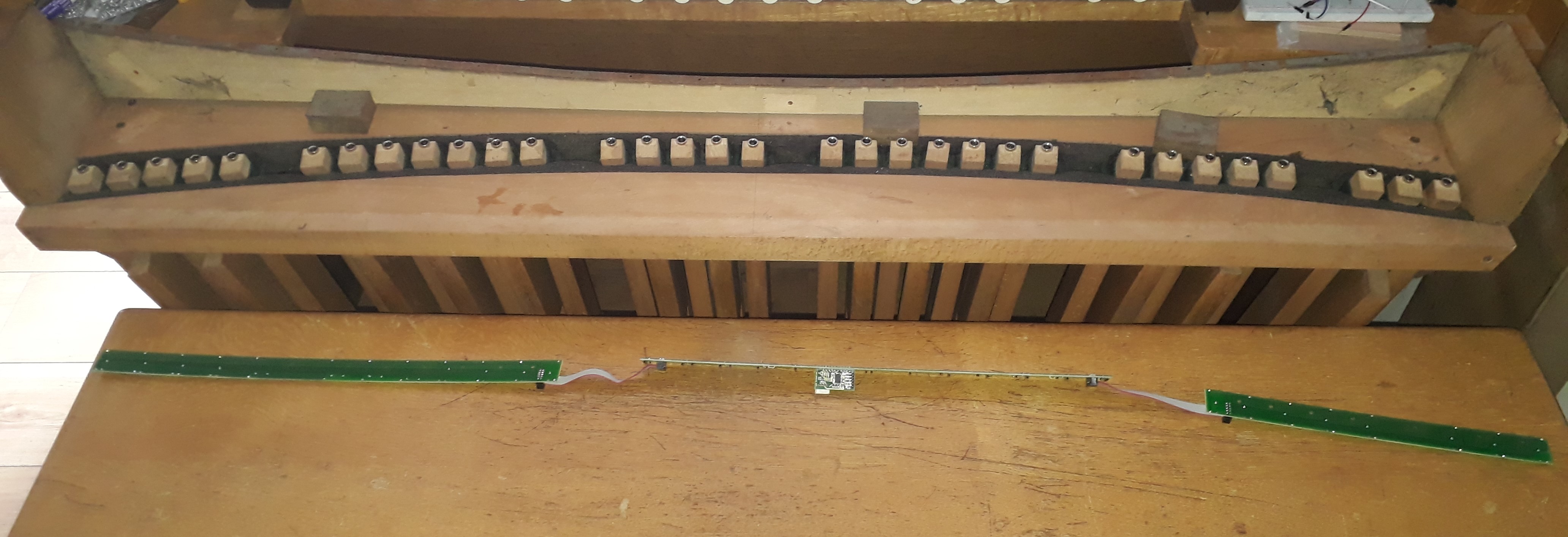

Meanwhile, this evening I indulged in a little creative destruction. The pedalboard contacts are a mixture of 3-wire and 4-wire contacts, and are badly damaged. Those which are not damaged are corroded:

Given a choice of cleaning the corroded contacts and replacing the damaged ones, or swapping the whole lot out for reed switches, the choice of the latter was the obvious one. Reed switches, which are controlled by proximity magnets, are a bit fiddly to set up initially, but once installed are far more reliable and need no maintenance. So this evening I removed the old contact assemblies. Here is the denuded pedalboard, just needing a bit of a brush down. You can clearly see where the contacts were secured.

I have two new strips of pedal felt, but on closer inspection of the business end of the pedals it would appear that the existing felt is in fairly good condition, and not significantly compacted. Still debating whether or not to replace it.

For now, I believe it is time for tea.