Rumours of my demise have been greatly exaggerated. I have, however, been even more busy this month than I predicted. February isn’t looking much better either.

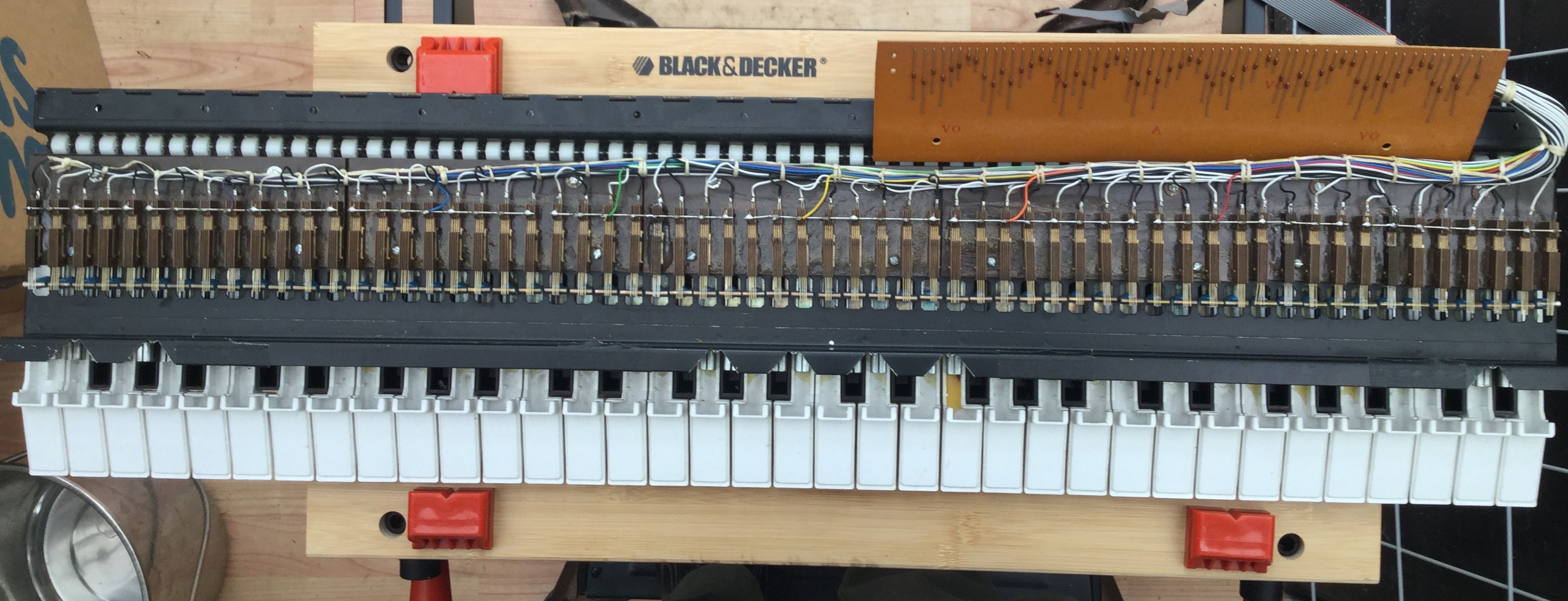

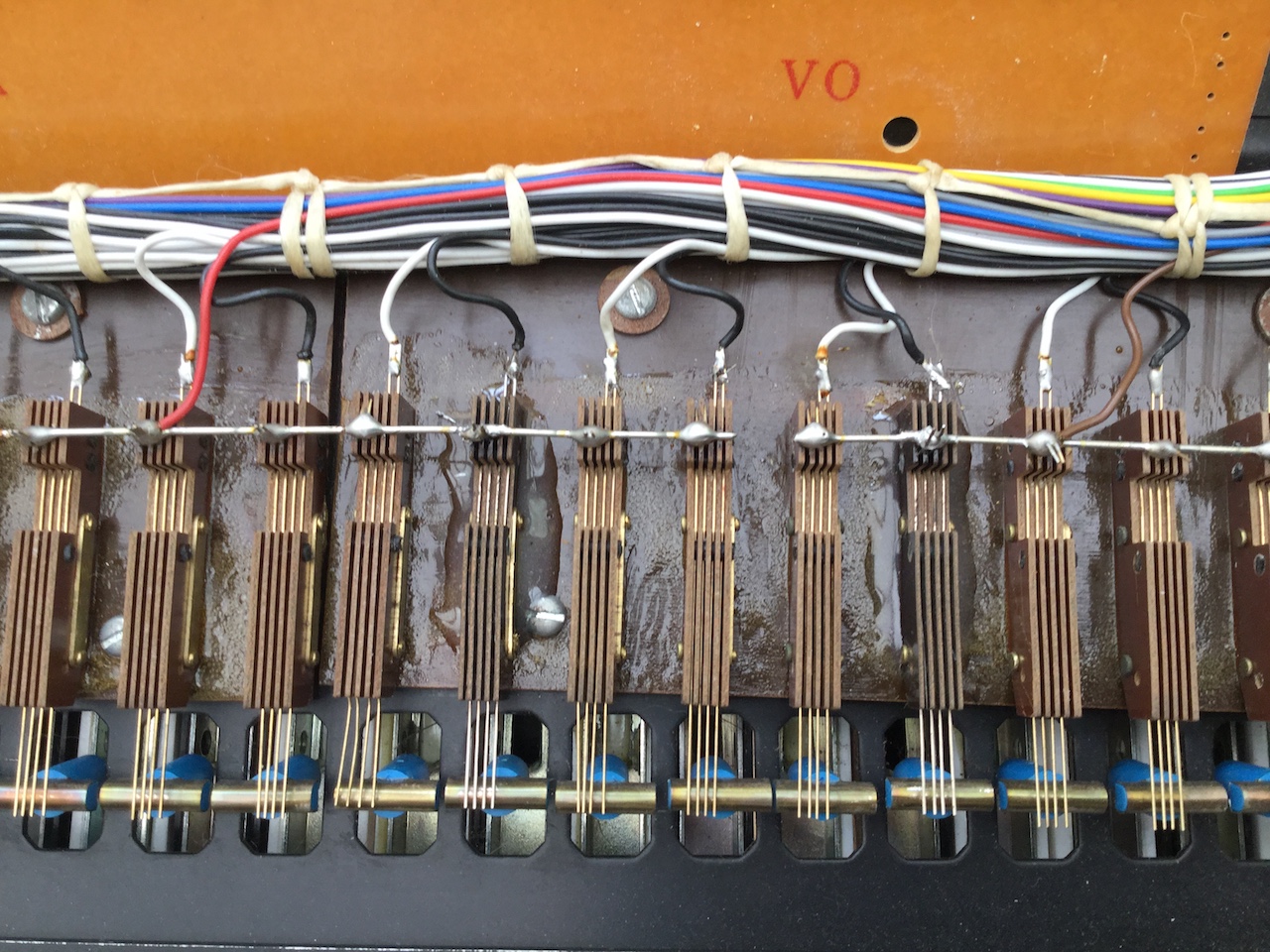

The second switch arrived earlier this month. It is similar, but superior, to the first, in that it has a silent action. There are two drawbacks. Firstly, the button part in the centre is somewhat smaller than is comfortable; and secondly, the shiny new metal looks entirely out of place on the old console. The first problem could be addressed by using the 19mm switch instead of the 16mm one, but the second is obdurate. Time for Plan C; the nice man from Norwich Organs is looking for 40 Kimber Allen pistons, which he believes may be in a box in the garage (along with half the clutter in the universe).

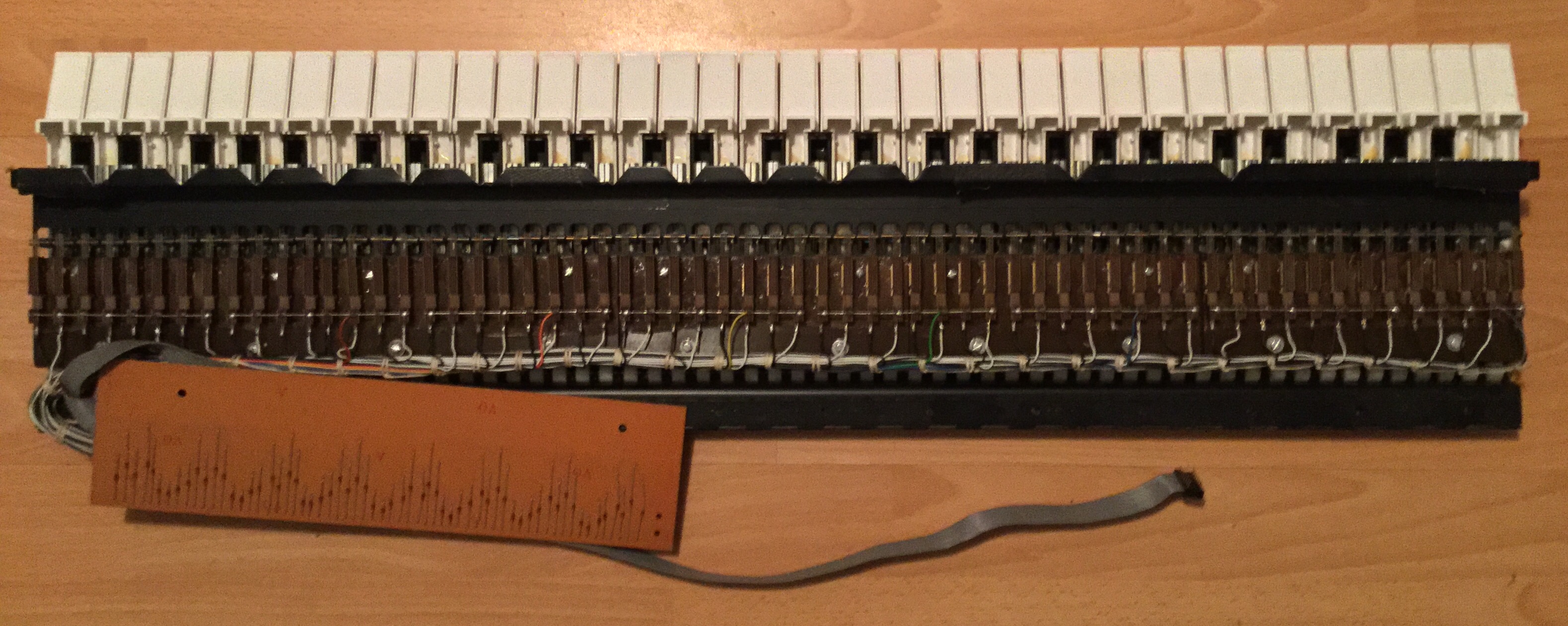

Meanwhile, the oak frame of the choir manual has the broken-off end of a screw in it. I suggested that, since it would be completely covered by the frame of the great manual, I could simply drill another hole for a fixing screw. This was met with a shocked and mildly outraged, “But I would know it was there!” Not willing to argue with a craftsman, I rendered up the frame for a quick repair job.

Hopefully I will be able to do something on the project in February. Once I have confirmation that I have the requisite amount of Kimber Allen pistons, I can at least send the piston rails off for drilling. Beyond that, I hope that I can start buying some MIDI components in March.

Dogs are doing very well, and have become fast friends. They now go everywhere joined at the hip, and if one of them has to go out alone for a trip to the vet, the other one sits in the middle of the lounge and sulks.