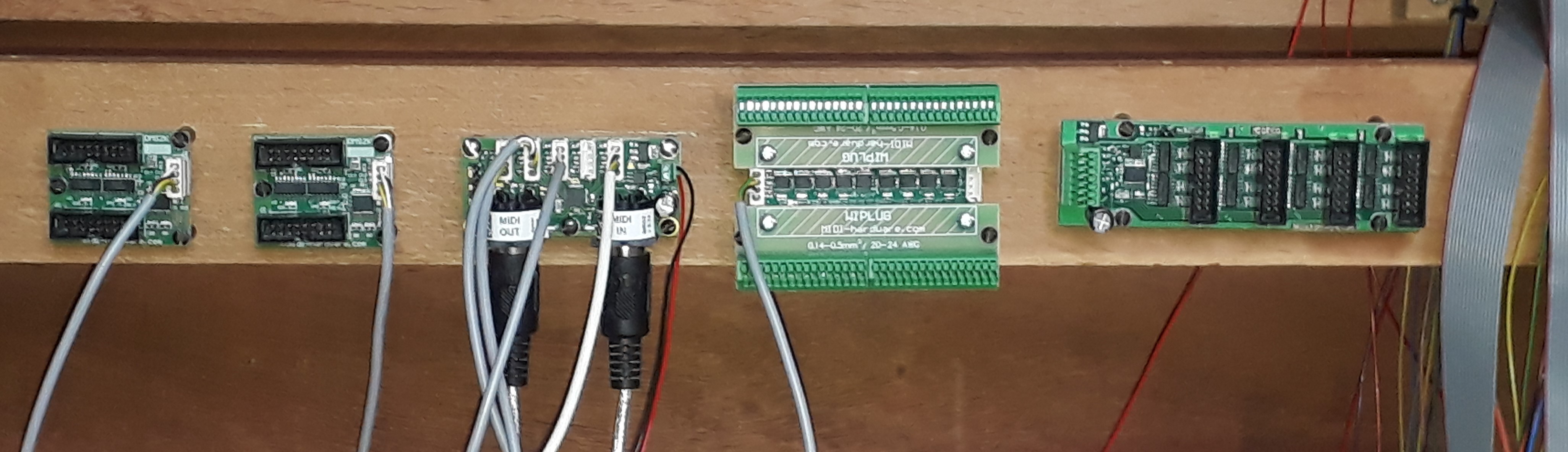

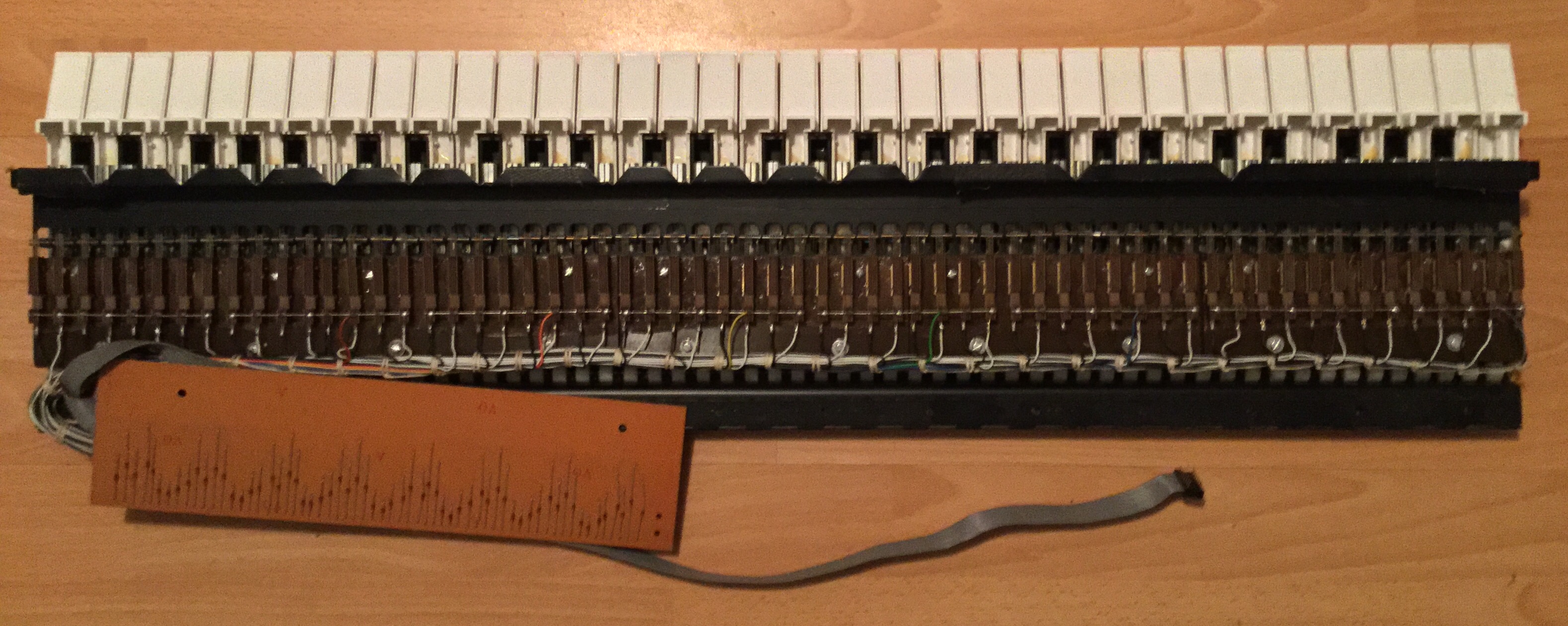

Still ridiculously busy, but hope to have more free time later this month to work on the pedal reed switches. I am also in discussions with Mr Norwich Organs about the swell pedals and concomitant adjustments to the kneeboard. In the meantime, I have finished affixing the MIDI modules to the console:

Beautiful, is it not? Pay not attention to the apparently wonky placement of the module on the right – it is perfectly straight; your eyes are crooked.

There is enough space on this board to fit several additional modules should they be required. I think I may actually run out of space on the MRG2, and will need an additional one at some point. However, that is a problem for future consideration.

In dog-related news, Mia’s space on the bed (but not her space in my heart) is now occupied by Bailey, another rescue – a younger bullmastiff/French mastiff cross. She is boss-eyed and has no hips (at the moment; she’s dieting), but she is quite gorgeous, and very affectionate. She has immediately adopted Betty as her foster-mother, and Betty has stoically accepted the same. She gives me long-suffering looks whenever I glance her way, but I have secretly observed her wagging her tail and allowing Bailey to share her sofa. She’s not as tough as she likes me to think.