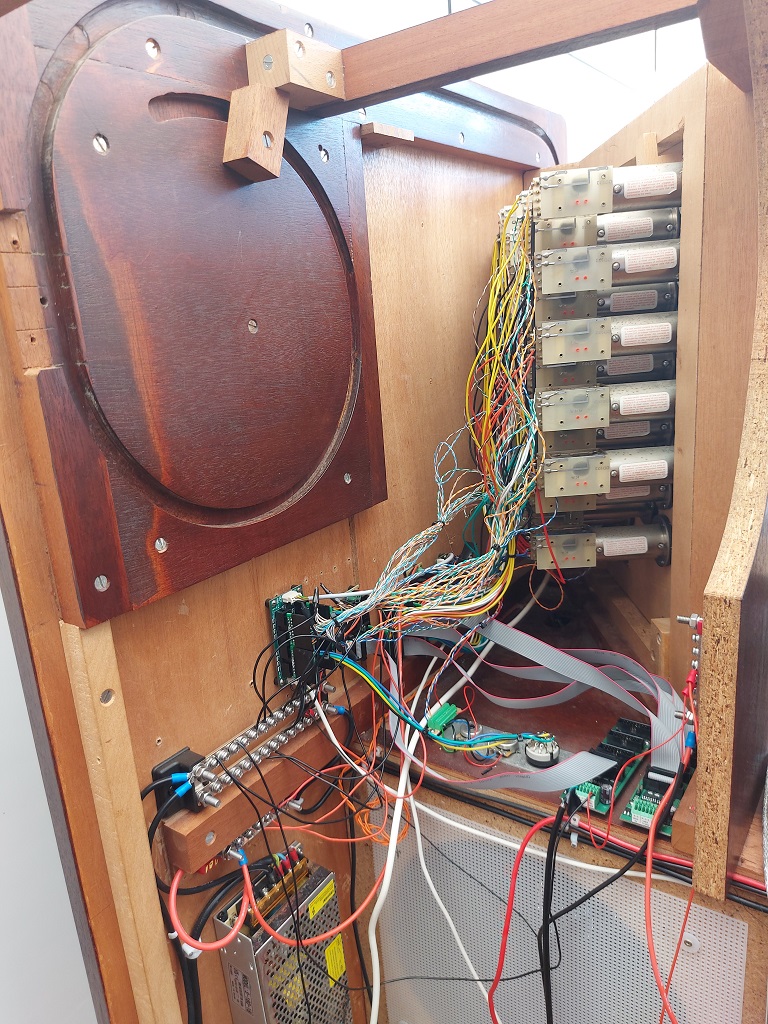

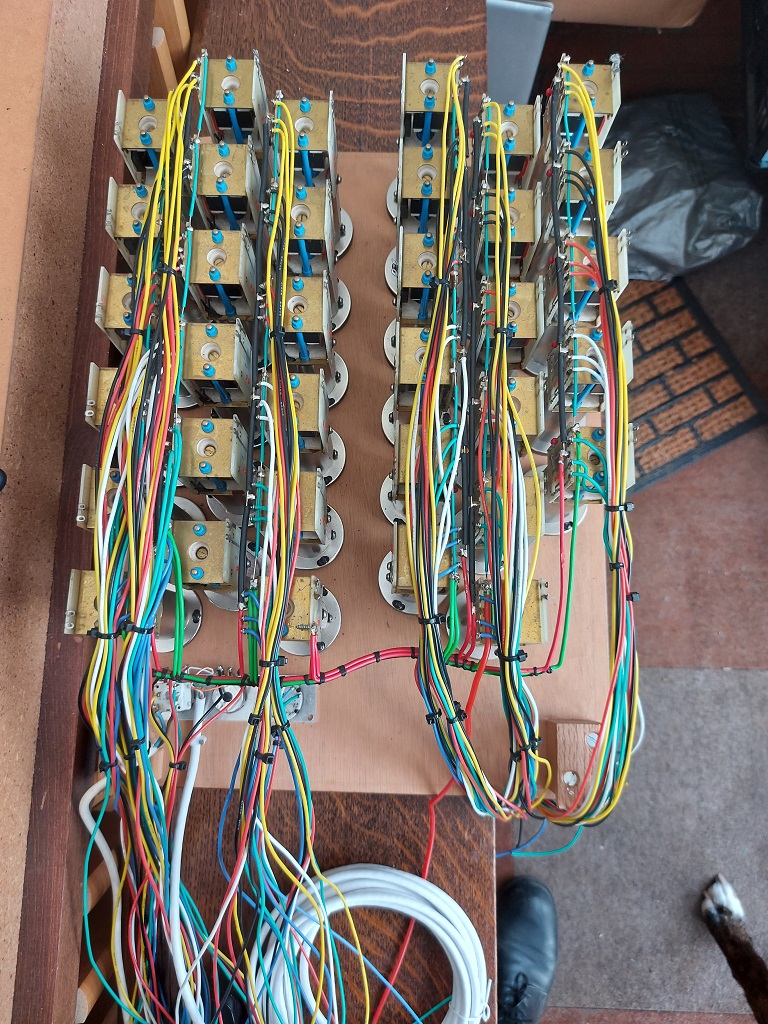

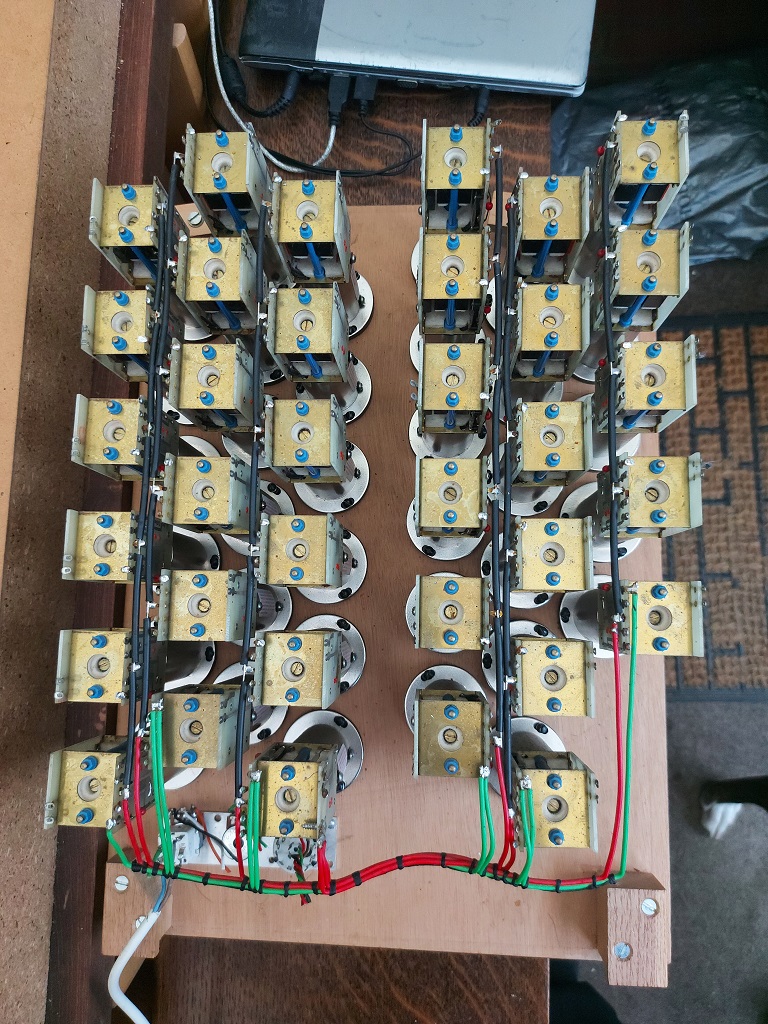

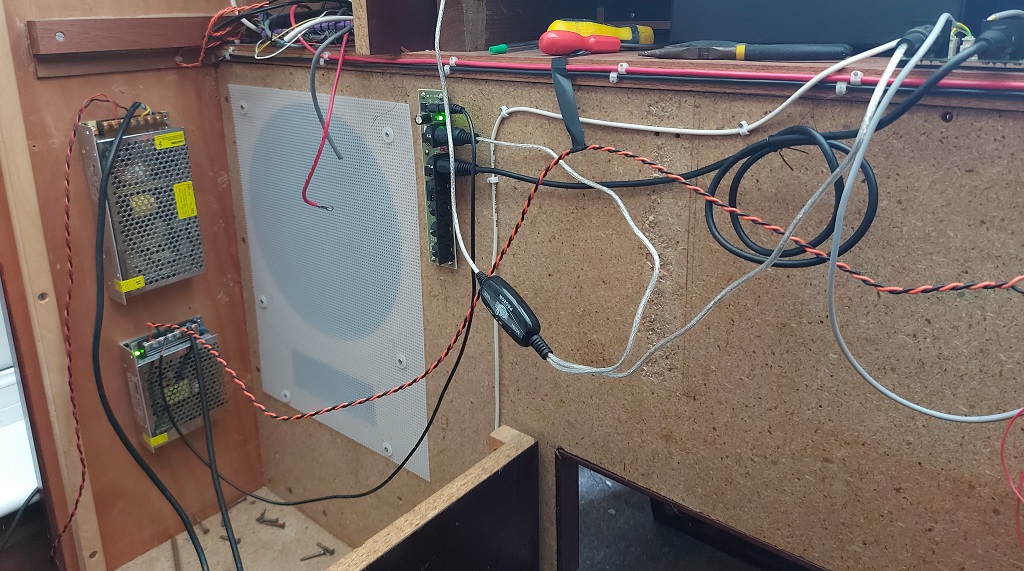

I am pleased to report that the SAMs all work exactly as they are intended to work. Everything is now wired up on the right-hand jamb, and all MIDI messages are generated and received correctly.

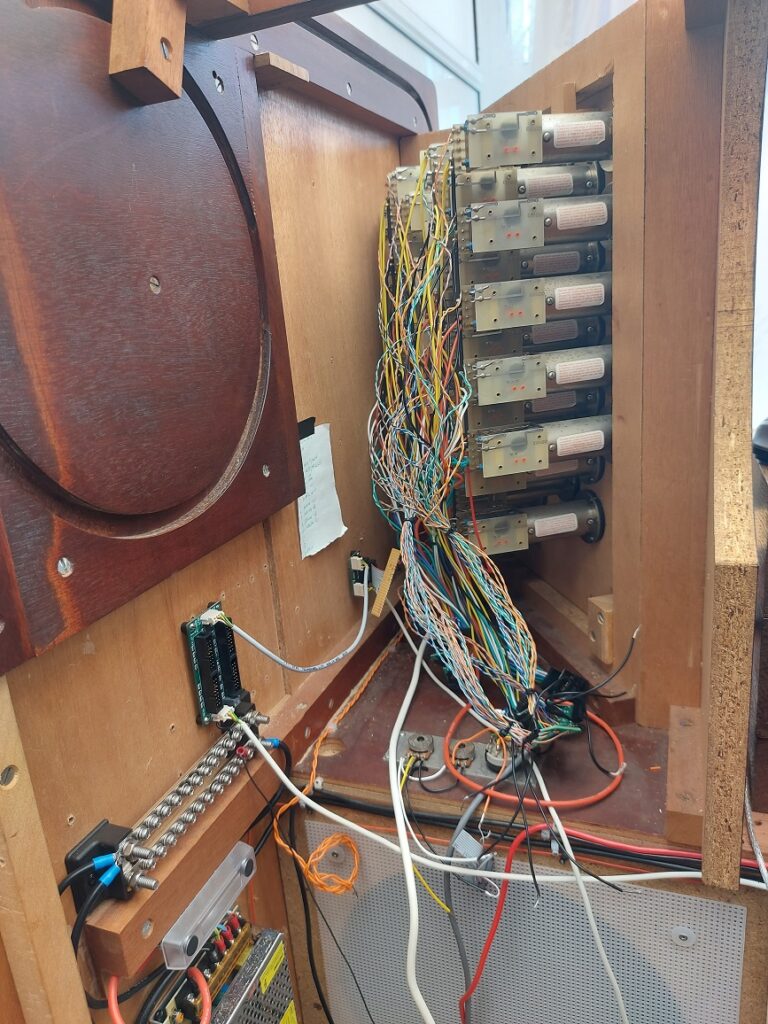

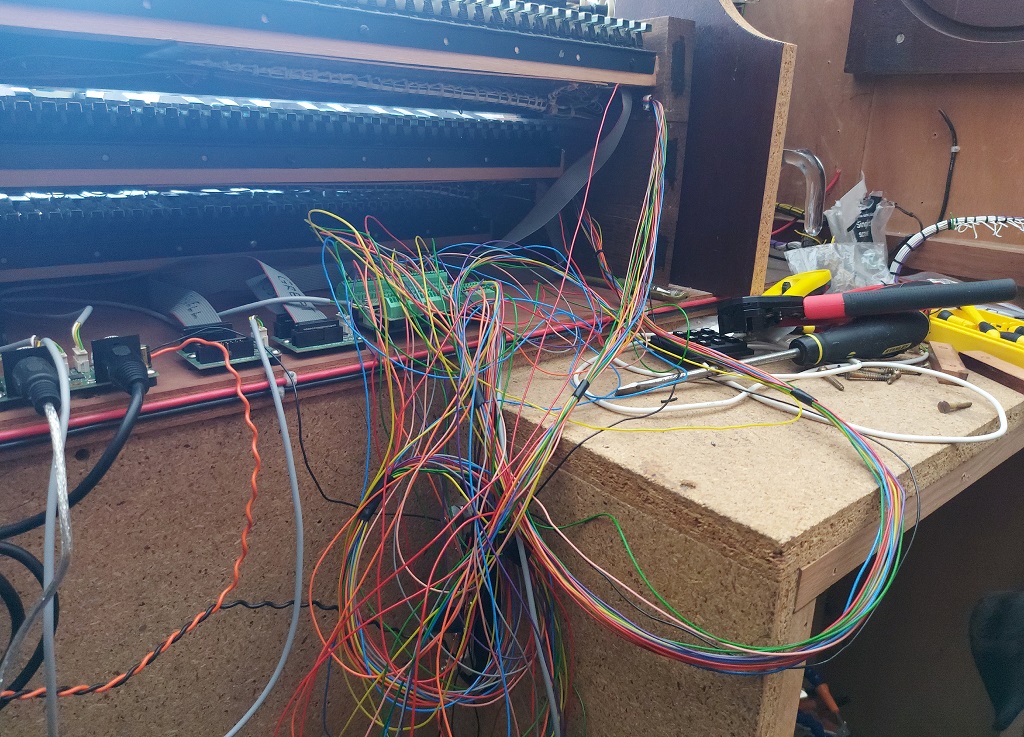

There is a little bit of noise from one of the pots, which only appears when both MIDECO boards are wired up. There is no connection between the MIDECO and the POT12 controllers, so RFI must be the culprit again. Moving the POT12 board removes most of the noise, and reducing the bit field of the pot removes the rest. This means that there is one pot with range of 0-31 (compared to 0-63), but that won’t be a problem. David is going to, ahem, ferrite out some ferrite beads to see if they help.

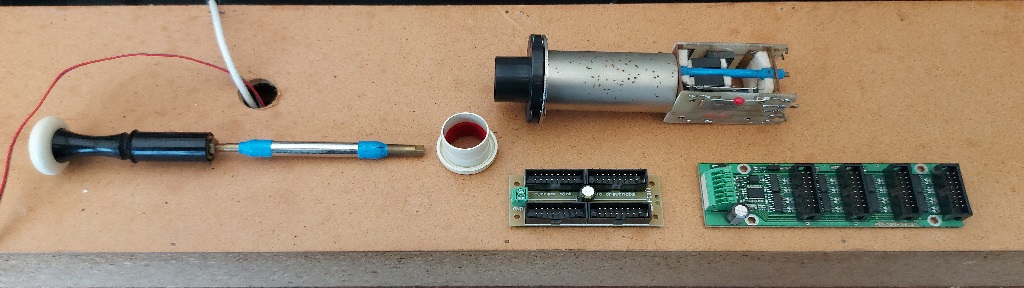

There are two sticky pistons. From the names on the stops (Great Enclosed, and Trompette En Chamade 8), I suspect that they were rarely used in the Lady Chapel of Buckfast Abbey – this may explain it. As per David’s instruction, I’m going to dismantle them both and see what is wrong.

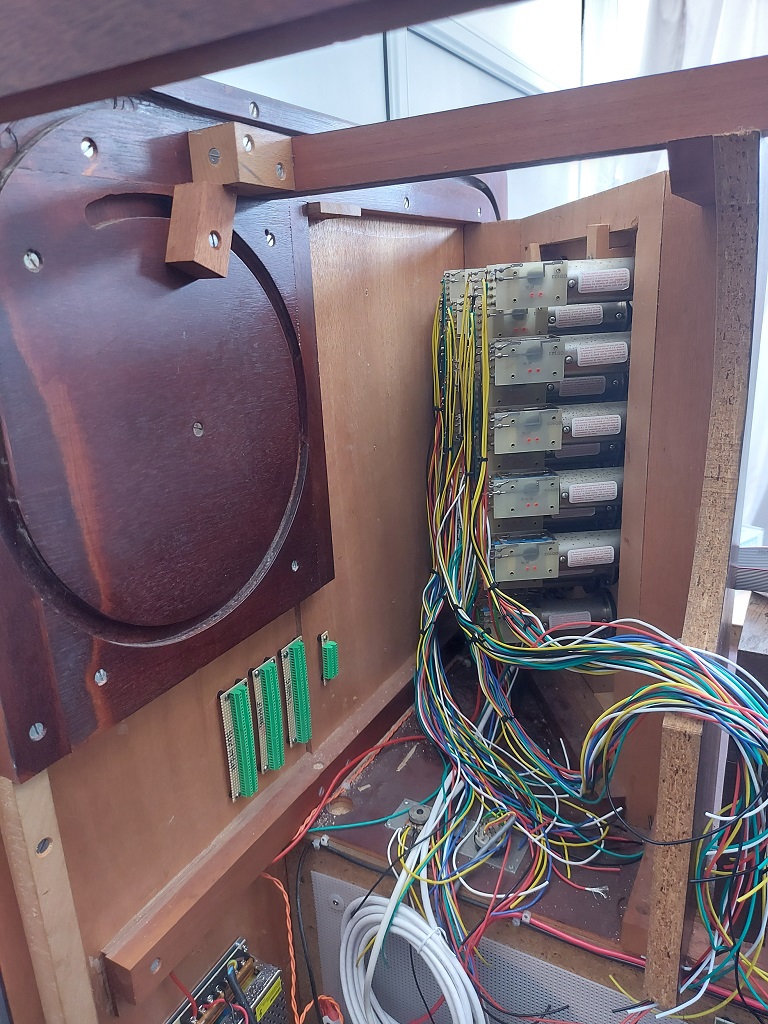

So I get to dismantle the jamb again. Yea, verily, my cup runneth over.